• Low cost with air conditioning system

• Internal air flow circulation

• Obtional with humidity controlling system

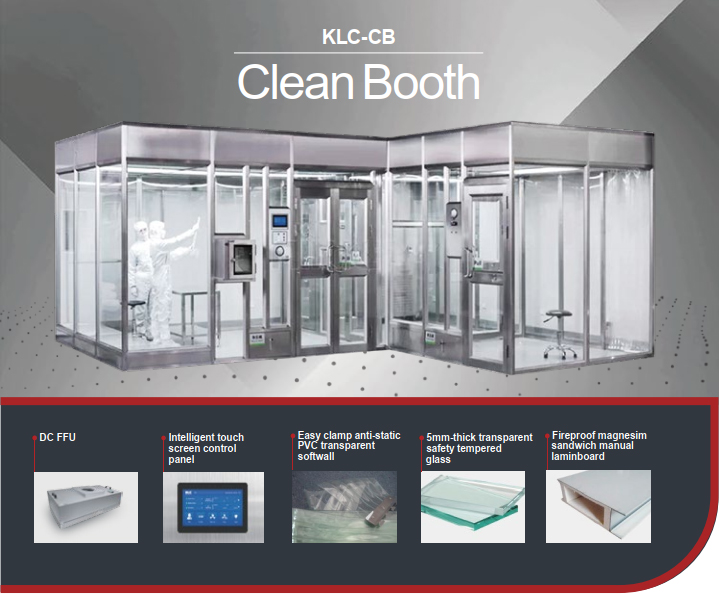

Item NO. :

K-CB5Clean class :

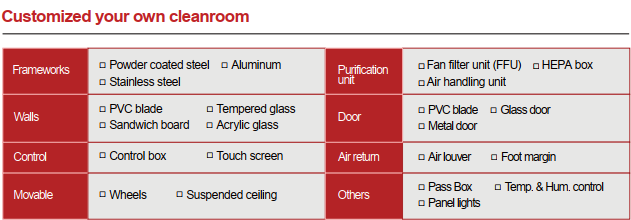

ISO5/6/7/8/9Frameworks :

Epoxy powder coated steel / Stainless steel square pipe / Extruded aluminumWall material :

Anti-static strip curtain / Anti-static grid curtain / Sliding door/ Tempered glass / Laminated glassCeiling material :

Stainless steel / Cold-rolled steel with powder coated / Anti-static grid curtain / Anti-static acrylic boardA cleanroom with air conditioning is a specialized controlled environment designed to minimize contaminants such as dust, airborne particles, and microbes. It combines the features of a cleanroom, which is a sealed environment with strict particle control, and an air conditioning system, which regulates temperature and humidity.

Cleanrooms with air conditioning are commonly used in industries that require high levels of cleanliness and precision, such as pharmaceuticals, electronics, biotechnology, and aerospace. These environments are essential for research, manufacturing, and testing processes that demand strict quality control.

The air conditioning system in a cleanroom plays a crucial role in maintaining optimal conditions. It filters the air, removing particles and contaminants, and controls the temperature and humidity levels within the specified range. This prevents the accumulation of dust and moisture, which can compromise the integrity of sensitive products or experiments.

The air conditioning system in a cleanroom typically consists of high-efficiency particulate air (HEPA) filters, which are capable of removing particles as small as 0.3 microns with a high efficiency. The filtered air is then circulated and conditioned to meet the required temperature and humidity specifications.

Freatures

1. Contamination control: The combination of a cleanroom and air conditioning system ensures a controlled environment with exceptionally low levels of contaminants. This is crucial for industries where even tiny particles or microorganisms can cause product failures or compromise research results.

2. Temperature and humidity control: The air conditioning system maintains stable temperature and humidity levels, which are often critical for processes involving sensitive materials or equipment. It helps prevent condensation, corrosion, and other adverse effects caused by erratic environmental conditions.

3. Enhanced product quality: By minimizing contaminants and maintaining optimal conditions, cleanrooms with air conditioning contribute to higher product quality and reliability. This is particularly important in industries that deal with sensitive electronics, pharmaceuticals, or precision manufacturing.

4. Worker comfort: Air conditioning not only benefits the products or experiments but also provides a comfortable working environment for personnel inside the cleanroom. Regulated temperature and humidity levels can improve employee productivity and reduce fatigue.